If you have been using manual machining for a while and wishing for an upgrade as soon as possible, you should learn about CNC machining. Over the years, various innovative manufacturing processes have been introduced; however, the most widely used mass production of metal and plastic parts is precision CNC machining. Computer Numeric Control machining or CNC machining refers to an automated manufacturing process with computer commands. Since the 1960s, precision machining has become the industry standard for producing complex machine parts with maximum accuracy.

How Does Precision CNC Machining Work?

Most manufacturing companies today are turning to CNC machining to reduce the inconsistencies and errors of manual laboring. As mentioned before, precision CNC machining refers to how a computer program creates the process that can be read by the CNC machine. The operator of a manufacturing unit produces a file that can be read and understood by the CNC machine, with CAM or CAD software. After this, the machine handles all the work assigned to it by following the program’s instructions and you would only have to retrieve the final product. With the assistance of precision machining technology, companies can manufacture complex components by maintaining a tolerance standard of 0.0001 “.

The Capability of Precision CNC Machining

The capability of precision CNC machining refers to how the machine can create machine parts while maintaining maximum accuracy and following the task’s specification. Regardless of the size and the complexity of the object, an operator can manufacture exact outputs effortlessly. Some manufacturing tasks require a certain accuracy level to be made ready for assembling into the final product. The CNC machining helps manufacturers achieve this level of consistency across different shapes and sizes of objects.

What are Some of The Common Types of Precision CNC Machining?

Precision CNC machining offers numerous benefits over other machining techniques, including reduced cycle times and improved finishes. All these types of CNC machining types mentioned here will be suitable for manufacturing sectors where bulk volumes need to be produced within a short time while ensuring precision.

1. CNC Turning Machines

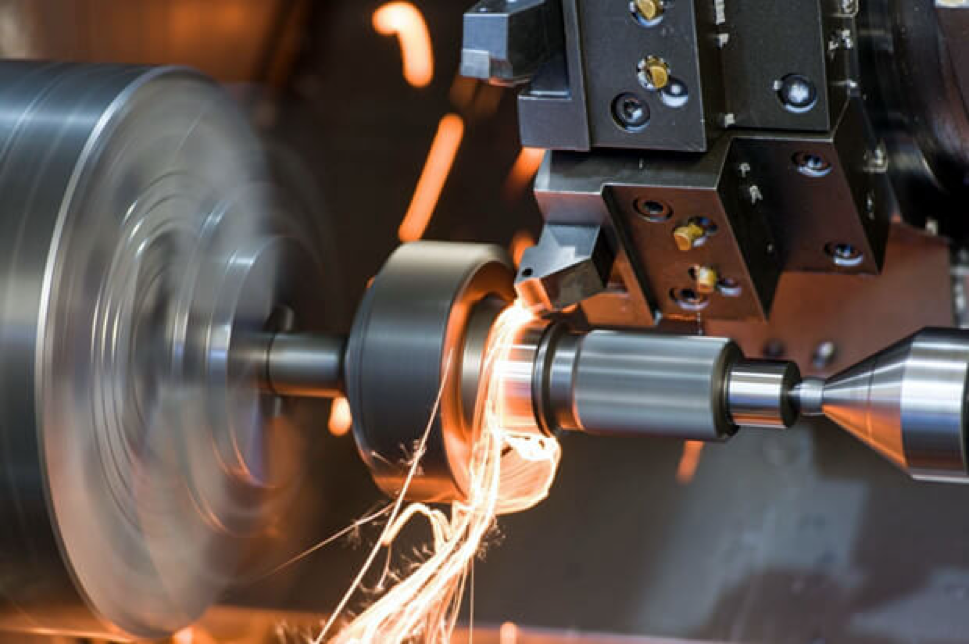

The distinct characteristics of these types of lathes are that it can rotate the materials during the operation. To cut materials using this precision CNC machining, you will have to place the cutting tools in the rotating bar. These CNC turning machines follow a holding technique, which offers better support and results in higher tolerances. CNC lathing machines create internal and external features on the machine parts, including drilling holes, making slots, threads, broaches, etc.

2. CNC Milling Machines

Like CNC lathes, the milling machines also follow the holding technique, and thus the cutting tool rotates while holding the component. This type of precision CNC machining is useful for producing diverse shaped machine parts exhibiting multiple features, and you can create slots and threads in rectangular shaped parts as well.

3. CNC EDM

With the help of CNC EDM or Electric Discharge Machine, you can mold materials into desired shapes using the controlled sparks of this precision CNC machining. The component you are willing to cut should be positioned under the electrode wire, which emits an electric discharge when programmed by the CNC machine. EDM is best suited for hard workpieces that are difficult to shape and angle according to the requirements of the task.

4. CNC Laser Machines

If you want to slice or engrave machine components while ensuring high precision, this precision CNC machining would be appropriate for your workspace. The entire engraving and slicing take place when a beam is focused from the pointed router. When the laser heat comes in contact with the material, it starts melting, and then the cuts are formed.

These CNC machining services can create a ton of varying designs that other forms of precision machining techniques like milling and turning cannot perform. CNC laser machines are used in manufacturing units for marking or decorating finished parts. With the help of laser engraving, you can machine your logo onto the CNC milled products.

If you are searching for CNC machining online, you should check the CNC machining services of Bruico. Bruico has been serving customers for 10 years, and they are the one-stop solution for all your CNC machining requirements.