SMT PCB assembly is one of the most widely used methods in modern electronics manufacturing, enabling compact, high-performance, and cost-efficient circuit boards. As electronic devices continue to shrink in size while increasing in functionality, SMT PCB assembly has become the backbone of advanced PCB production across industries such as consumer electronics, automotive, telecommunications, medical devices, and industrial automation.

Understanding SMT PCB Assembly

SMT PCB assembly refers to the process of mounting electronic components directly onto the surface of a printed circuit board using surface-mount technology (SMT). Unlike traditional through-hole assembly, SMT PCB assembly eliminates the need for drilled holes for most components, allowing higher component density and faster production cycles.

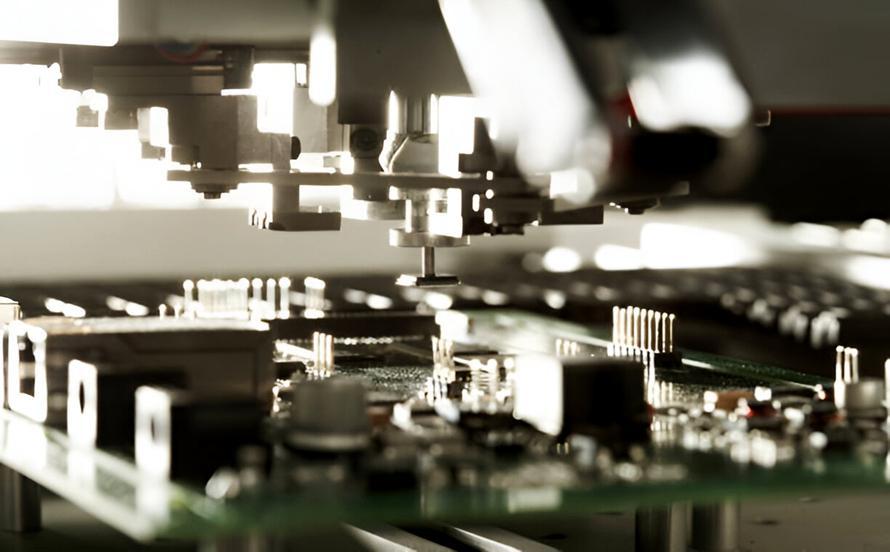

In SMT PCB assembly, components such as resistors, capacitors, ICs, and connectors are placed on solder pads using automated pick-and-place machines. This method supports miniaturization and high-speed manufacturing, making SMT PCB assembly the preferred choice for modern electronic products.

Key Steps in SMT PCB Assembly

The SMT PCB assembly process involves multiple precise stages to ensure high-quality and reliable circuit boards.

Solder Paste Printing

The first step in SMT PCB assembly is applying solder paste onto the PCB pads using a stencil printer. The solder paste acts as an adhesive and electrical connection medium for surface-mount components.

Component Placement

After solder paste application, automated pick-and-place machines position surface-mount components onto the PCB with high accuracy. This step is crucial in SMT PCB assembly to ensure correct alignment and optimal performance.

Reflow Soldering

In the reflow soldering stage, the PCB passes through a reflow oven where the solder paste melts and forms strong electrical connections between components and the board. Controlled temperature profiles are essential in SMT PCB assembly to prevent defects such as solder bridging or tombstoning.

Inspection and Testing

SMT PCB assembly includes inspection processes such as automated optical inspection (AOI), X-ray inspection, and in-circuit testing (ICT). These quality control measures ensure that the assembled boards meet industry standards and functional requirements.

Final Assembly and Packaging

After testing, the PCB undergoes final assembly, cleaning, and packaging before delivery. This ensures that SMT PCB assembly products are ready for integration into electronic devices.

Advantages of SMT PCB Assembly

SMT PCB assembly offers numerous advantages over traditional assembly methods. Higher component density allows designers to create compact and lightweight devices. Faster production speeds reduce manufacturing costs and time-to-market. Improved electrical performance and reduced signal interference are additional benefits of SMT PCB assembly.

Another major advantage is automation. SMT PCB assembly relies heavily on automated equipment, ensuring consistent quality and scalability for mass production. This makes SMT PCB assembly suitable for both low-volume prototypes and high-volume manufacturing.

Applications of SMT PCB Assembly

SMT PCB assembly is used in a wide range of applications. In consumer electronics, it supports smartphones, laptops, and wearable devices. In automotive systems, SMT PCB assembly enables advanced driver-assistance systems, infotainment units, and engine control modules. Telecommunications equipment, medical devices, industrial machinery, and IoT products also rely on SMT PCB assembly for reliable and efficient circuit board production.

Challenges and Quality Considerations in SMT PCB Assembly

Despite its advantages, SMT PCB assembly presents challenges such as solder defects, thermal stress, and component misalignment. Effective process control, optimized design, and rigorous testing are essential to minimize these issues. Selecting appropriate materials, stencil design, and reflow profiles plays a critical role in achieving high-quality SMT PCB assembly outcomes.

Future Trends in SMT PCB Assembly

The future of SMT PCB assembly is driven by trends such as miniaturization, high-frequency applications, and advanced packaging technologies like BGA and QFN. As electronic devices become more complex, SMT PCB assembly will continue to evolve with smarter automation, AI-driven inspection, and environmentally friendly manufacturing processes.

Conclusion

SMT PCB assembly is a critical technology for modern electronics manufacturing, offering unmatched efficiency, scalability, and performance. By adopting advanced SMT PCB assembly techniques, manufacturers can achieve superior product quality and faster production cycles. If you are looking for reliable manufacturing solutions and long-term production support, partnering with a professional PCB assembly company ensures high-quality SMT PCB assembly, advanced quality control, and cost-effective production tailored to your project requirements.